QJ-L QJ-T型起重機立式減速器

QJ-L QJ-T Crane Vertical Decelerators

一、概述Brief

起重機立式減速器部分(fēn)分(fēn)爲QJ-L,QJ-T兩個(gè)系列,主要用(yòng)于起重機運行機構,也(yě)可(kě)用(yòng)于運輸.冶金,礦山、化(huà)工、輕工等各種機械設備的(de)運行機構中。齒輪.齒輪軸采用(yòng)中碳合金鋼中硬齒面,具有結構緊湊、承載能力較高(gāo)等優點,是我廠繼Zsc型、ZSC(A)型減速器之後推出的(de)又一代新産品。

The Crane verticl decelerators has two series,type QJ-L and type QJT. They are the operating mechanism of crane and other machinery in transportation, metallurgy, mining, chemical industry and light industry. The gear and axle are made of middl carben alloy steel and middle carbide-faced, which are fastened structure with high carrying capacity. Such kind of reducers are our updated decelerators after ZSC and ZSC(A) reducers.

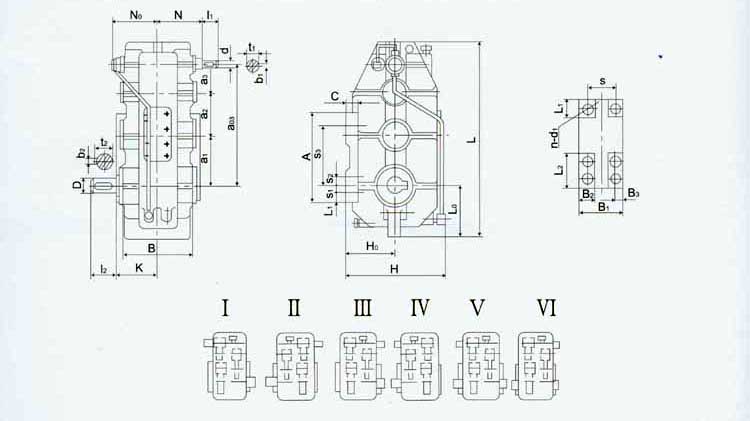

二、QJ-L型減速器外形、尺寸及裝配型式

Outlook, assembling size and installing form of QJ-L reducer

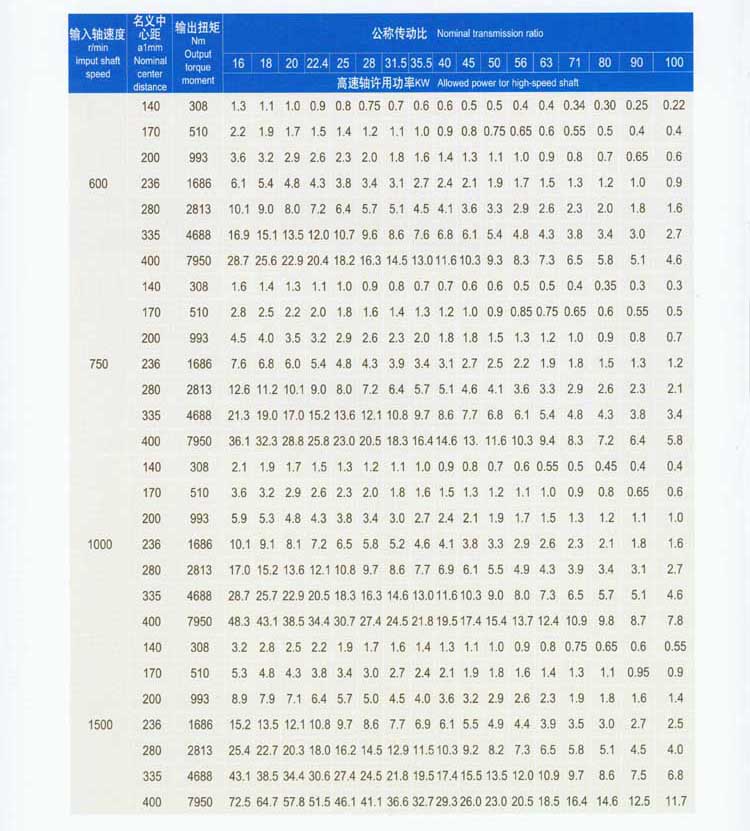

四、QJ-L, QJ-T型減速器承載能力表

Allowed power and output torque of QJ-L, QJ-T reducer

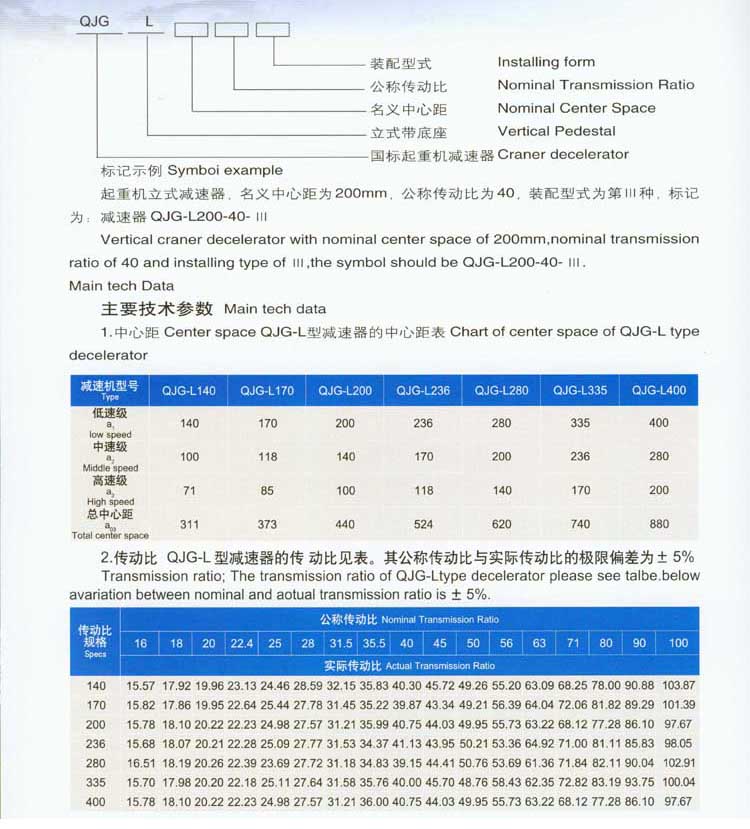

QJG-L型起重機立式減速器QJG-L type reducers

根據******标準JB/T8905.3-1999生産QJG-L型減速器主要用(yòng)于起重機的(de)小車運行機構和(hé)部位讓式起重機、裝卸橋等大(dà)車運行機構中,也(yě)可(kě)用(yòng)于其它需要立式安裝的(de)設備傳動。

Whichare produced on basis of JB/T8905.3-1 999,are mainly applied in craning,parts craning and Loading-unloading bridge.Also they can be applied in other vertical installing machines.

特點Property:

1.QJG-L型減速器采用(yòng)鑄鐵箱體,底座式側面安裝立式減速器;

2.三級傳動,速比爲16-100;

3.該系列有7種規格,名義中心距爲140-400mm;

4.小規格減速器爲油浴式潤滑,280以上的(de)減速器采用(yòng)集中噴油潤滑。

其它特點同QJ型減速器。

1.Casting iron box is applied in QJG-L type decelerator and at side of pedestal the vertical decelerator is installed;

2.Three stage transmission with speed ratio of 16-100;

3.Seven rinds of specs for QJG-Lseries and nominal center space of 140-400mm;

4.Qil bathing lubrication for small size machines and central oil spuring lubrication for machines over 280.

型式Type

1.結構型式:QJG-L型減速器爲三級立式帶底座減速器。

2.裝配型式,QJG-L 型減速器共有六種裝配形式,見圖

1.Structure type:three stage vertical reducers with pedestal.

2.Installing type:There are six installing types for QJG-L type reducers which are showed below,

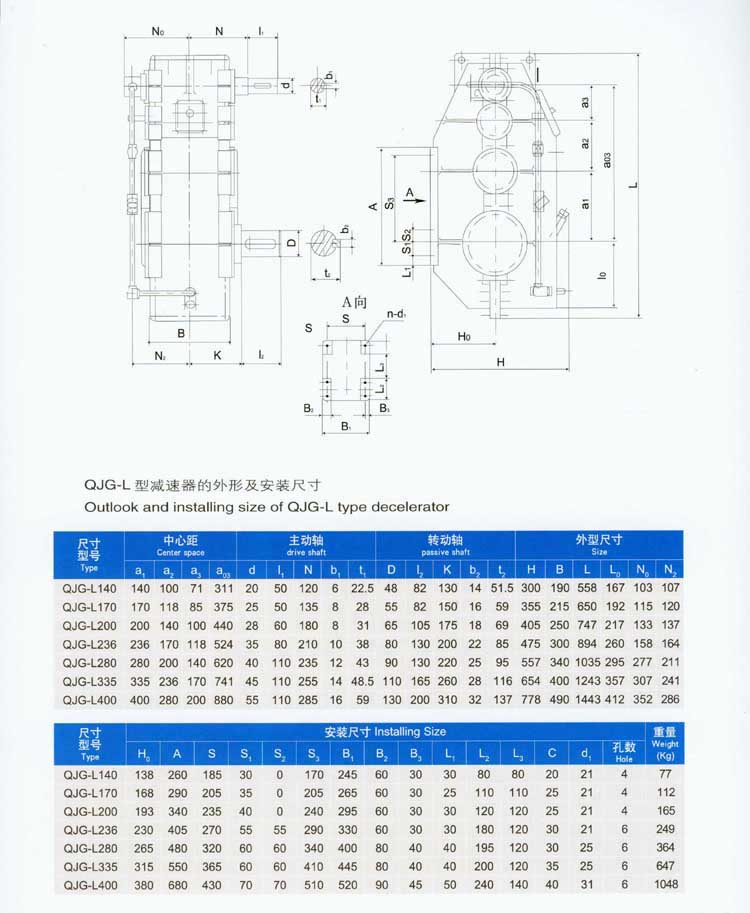

外形及安裝尺寸Outlook and nstalling size

QJG-L型減速器的(de)外形及安裝尺寸見圖和(hé)表

The outlook and installing size of QJG-L type decelerator are shown in graph and chart below.

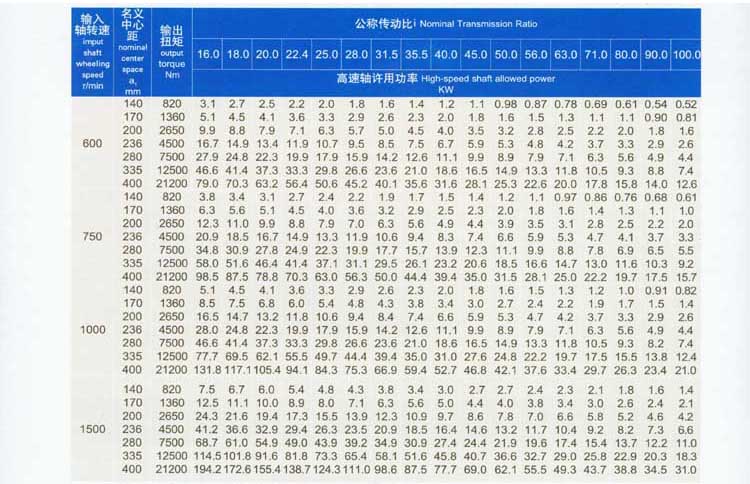

承載能力Carrying Capacity

QJG-L型減速器當工作級别爲M5時(shí)的(de)輸出轉矩和(hé)高(gāo)速軸的(de)許用(yòng)功率見表

stage of M5please check table below.

QJG-L型減速器的(de)輸出轉矩和(hé)高(gāo)速軸許用(yòng)功率(工作級别爲M5)

Output torque and high-speed shaft allowed power of QJG-L type decelerator(working stage of M5)

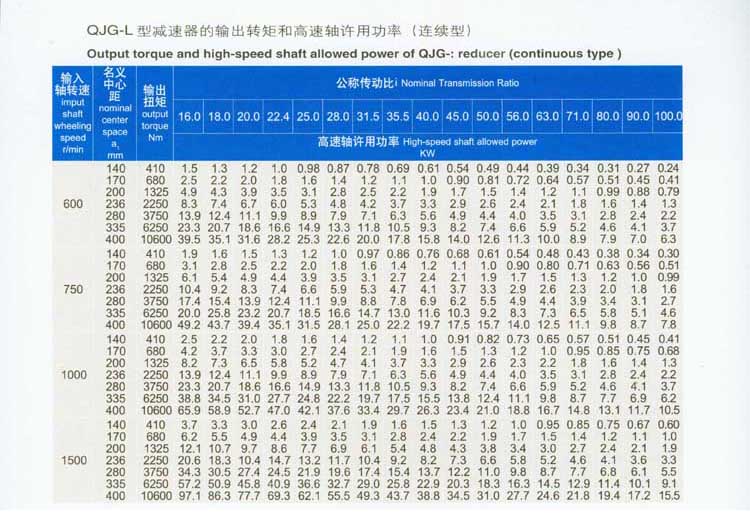

QJG-L型減速器爲連續工作時(shí)的(de)輸出轉矩和(hé)高(gāo)速軸的(de)許用(yòng)功率(見下(xià)頁)

Output torque and high-speed shaft allowed power for continuous QJG-L type decelerator

減速器輸出軸端的(de)瞬時(shí)允許轉矩爲額定轉矩的(de)2.7倍。

QJG-T型起重機套裝式減速器

QJG-T型減速器是QJG-L型減速器的(de)基礎上派生的(de),主要用(yòng)于起重機的(de)運行機構,也(yě)可(kě)用(yòng)于其它機械需要立式套裝的(de)傳動中,用(yòng)以代ZSC(A)型減速器

The temperary allowed torque of output shaft edge is 2.7 tines of rated torque.

QJG-T craning decelerator

QJG-T craning decelerator,derived fron QJG-L type decelerator,is mainly used in Craning and other machines with vertical set-installing operation to replace ZSC(A) type reducer.

特點: Property

QJG-T型減速器的(de)輸出端爲圓錐套,減速器就套在主機的(de)被動軸上,将其端部固定,減速器的(de)重量也(yě)支承在該軸上。在箱體上部設有裝孔,通(tōng)過銷軸固定在支架上。

With cypinder output edge,the QJG-L reducer is installed on passive shaft.The weight is there after sustained. the upper of case locates some holes to fastened onto shelf with screw shaft.

箱體分(fēn)三部分(fēn),部分(fēn)成“⊥”形,作立式減速器使用(yòng),下(xià)箱體油不易滲漏,輸出軸中心線到下(xià)端極限位置尺寸比較小。其它特點同QJG-L型減速器.

The case is made up by three parts and some are shaed as vertical decelerator.The size between center line of output shaft and end position is rather small.other properties are the same as that of QJG-L reducers.

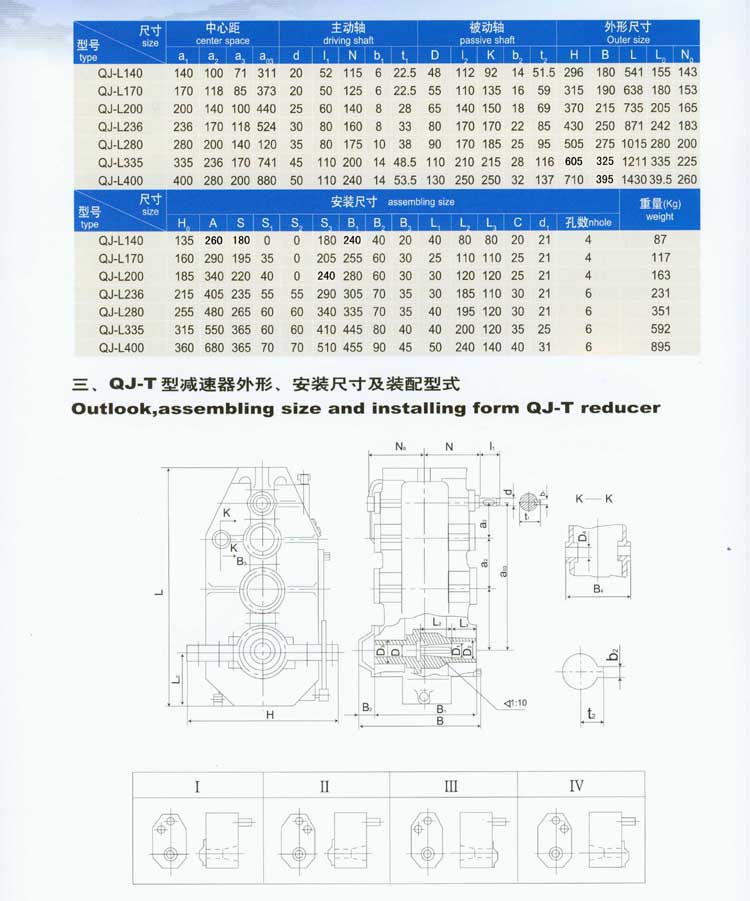

型式Type

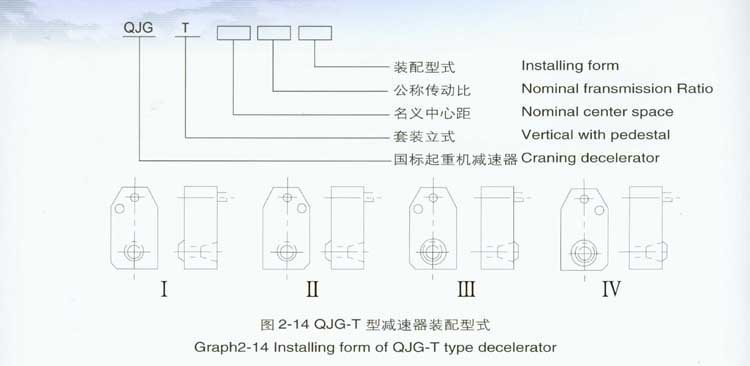

1.裝配型式QJG-T型減速器的(de)裝配型式有四種,見圖

2.軸端型式高(gāo)速軸采用(yòng)圓柱形軸伸,平鍵聯接,低速軸采用(yòng)空心軸套,錐形軸孔,平鍵聯接。

1.Installing type: There are four types for QJG-L type decelerator showed below,

2.Shaft edge type :Cylinder extension for high-speed shaft and shaft connection.

型号标記示例Symboi example

起重機套裝式減速器,名義中心距a,=200,公稱傳動比i=40,裝配型式第1I種,标記爲:減速QJG-T200-40-川I

Craning redueer,nominal center space a, =200,nominal transmission ratio i=40,instaling form is ll ,the sumbol is :reducer QJG-T200-40- I..

主要技術參數Main tech data

QJG-T型減速器的(de)中心距和(hé)傳動比與QJG-L型減速器相同。

Center space and transmission ratio of QJG-T reducer are the same as those of QJG-L reducers.

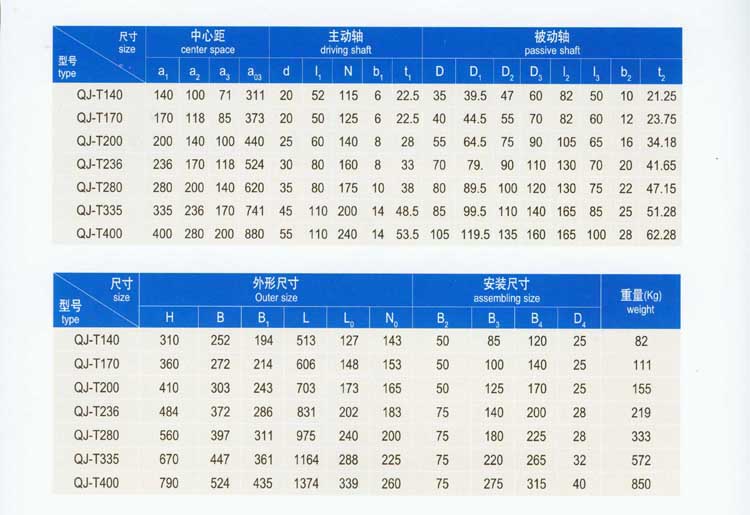

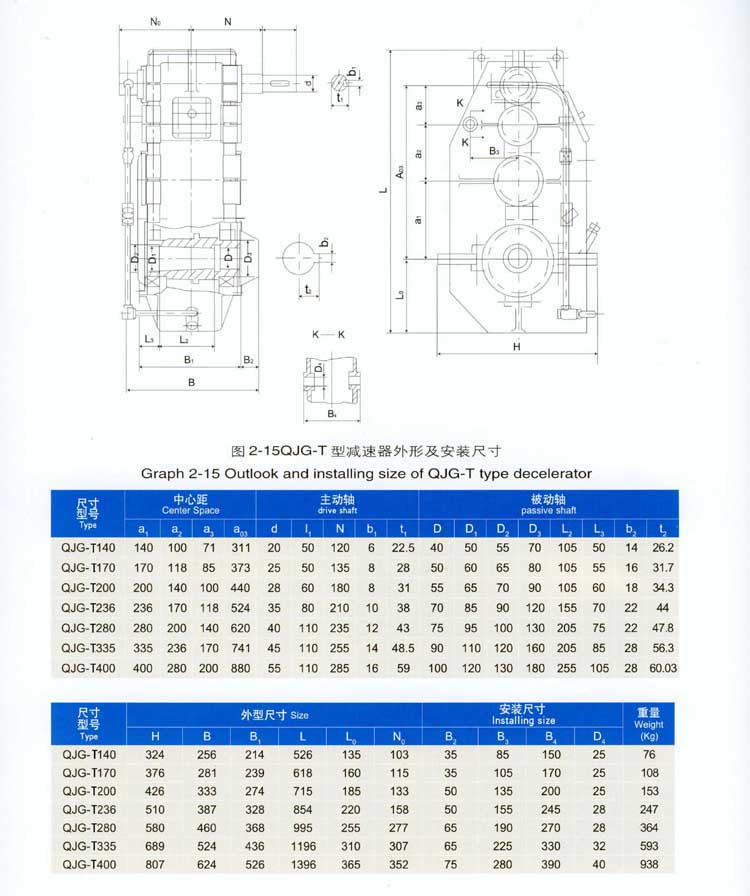

外形及安裝尺寸Contour and intalling size

QJG一T型減速器的(de)外形及安裝尺寸見表2-15和(hé)表2-20。

The contour and installing size of QJG-T type decelerator are shown in table 2-15 and 2-20. Loading capacity

承載能力Loading capacity

QJG一T型減速器的(de)輸出轉矩和(hé)高(gāo)速軸的(de)許用(yòng)功率與QJG一L型減速器相同.見表2-18QJG和(hé)表

The output torque and high-speed shaft allowed power of QJG-Tdecelerator and QJG-L decelerator .the related values art listed in table 2-18 QJG

選擇方法Selection method

選擇原則Selection principle

1)在選擇減速器時(shí),首先要滿足工作條件。即高(gāo)轉速,***大(dà)齒輪圓周速度,環境溫度和(hé)轉向等。

2)滿足機械強度的(de)要求,如輸入軸的(de)功率(或輸出軸的(de)轉矩) .軸伸的(de)***大(dà)徑向力和(hé)瞬時(shí)***大(dà)轉矩等。對(duì)于連續使用(yòng)的(de)減速器還(hái)要滿足熱(rè)功率。

3)滿足轉速要求.根據原動機的(de)轉速和(hé)工作機械的(de)要求轉速選擇***接近的(de)傳動比(***好是減速器的(de)實際傳動比,如果末給實際傳動比用(yòng)公稱傳動代替).一般兩者極限偏差2級爲土4%.3級爲土5%。如果特殊要求,我公司聯系特殊配制。

4)根據主機要求減速器的(de)安裝位置.界限尺寸。聯接部位、傳動性能的(de)要求.确定減速器的(de)結構形式,安裝型式和(hé)裝配形式。

5)根據輸入和(hé)輸出的(de)聯接方式,選擇軸端型式。

6)考慮使用(yòng)維修方便,選擇注油口,排油口的(de)位置,潤滑方式。散熱(rè)等。

1) the operating condition must be qualified when select decelerator.for example,the high speed rotation,max gear circle velocity,ambient temperature and rotation.

2) To meet mechanical intensity .for example,the input shaft power (or output shaft torque),.max radial force of shaft extension and intermittent max torque Aslo the heat power of continuous decelerator.

3) To meet rotationg speed .the most favorable transmission ratio should be selected according to the given rotating speed and required rotating speed (the actual transmission ratio,if not that,nominal transmission ration is favorable ).Usually the defference bettween them is 4%for 2 stage,5%for 3 stage.If there' s any special requirement,please contact us.

4)To determine structure mode, installing form and assembling type according to in stalling position,margin sizc.connecting place and driving property of decelerator.

5) To select connecting mode of input and output,to select shaft edge type.

6) To select oil inlet and outlet position ,lubricating mode and radiating.

選擇計算(suàn)Selecting calculation

1)QJ型(包括QJ一D/QJG-T,QJ-L)以及ZQA型減速器,用(yòng)于起重機各機構時(shí),根據GB3811《起重機設計規範》(以下(xià)簡《規範》的(de)規定,起重機機構的(de)工作級别分(fēn)爲M1-M8八種.本手冊所列的(de)承載能力爲M5工作級别,要用(yòng)在其它工作級别時(shí)應按公式進行折算(suàn)

式中

PMS=PMS x 1.12(1-5)KW

PMS-減速器承載能力表中的(de)高(gāo)速軸許用(yòng)功率值(KW);

PMI-相對(duì)Mi工作級别的(de)功率值(KW)

i一工作級别數1-8

2)起重機各機構疲勞計算(suàn)的(de)基本載荷 Mmax

a)起升和(hé)非平衡變幅機構

1) when QJ decelerator (including QJ-DJG-T,QJ-L type )and ZQA decelerator are applied in craning equipments,according to GB381 1<design stipulation of craning > ,there are eight working series M1-M8, the enclised loading capacity is M5. if other series is applied ,the followed formula is applied,

Where, PMS

一the hugg-speed sgaft akkiwed powed power in loading capacity table (Kw)

PMI一the powe of Mi series (KW)

1一 the working series 1-8

2) the basic leak load of craning MMAX

3) lofting and unbalanced structure

Mmax = φ6MN Nm φ6=1/2(1=φ2)

φ6一動載系數: φ6-load factor

Mn -電動機額定轉矩(Nm) Mn=motor rated torque (Nm)

φ2- -起升載荷系數,φ2=1-2 當起升速度高(gāo),系統剛度大(dà),操作猛時(shí),取值較大(dà)值。

見<規範>附錄B。

φ2 = liting load factor, φ2=1-2, If liting speed is high, large ragidity and heavy strike,

the larger value is preferable in <stipulation> appedix B.

b)運行和(hé)回轉機構operation and back-turning mechanism

Mmax=φ5x φ6mn

式中Where

ф5一彈性振動增大(dà)系數ф5=1.5-1.7 - stretching vibrant arising factor

ф8一剛性動載系數08=1.2-2.0

一rigid loading factor

ф8與電動機的(de)驅動特性和(hé)計算(suàn)零件兩側的(de)轉動量的(de)比值有關。見《規範》附錄P。the

value of 8is related to ratio between driving vharacter and moment of inertia.please see appendix PO.

平衡變幅機構Balance changing structure

疲勞計算(suàn)基本載荷取爲該零件承受的(de)等改幅靜阻力矩,其它零件取爲電動機額定力矩傳到該計算(suàn)零件力矩的(de)1.3-1.4倍。當瞬時(shí)***大(dà)轉矩低于2.7倍的(de)額定轉矩時(shí),可(kě)以進行靜強度校核,當超過此值時(shí),應驗算(suàn)零件強度,或者選大(dà)機座号的(de)減速器.

In leak calculation the basic load is determined by loaded resistance torque of the parts, for other parts,the basic load is 1.3-1.4 times of torque from motor rated torque to this related parts.You can check under silent intensyty should be checked and larger type of decelerator should be selected.

3.根據疲勞計算(suàn)基本載荷和(hé)轉速可(kě)算(suàn)出該工作級别的(de)功率值Pmi

3.The related power of this series can be calculated according to basic leak load and torque.

Pm=Mnx x n/9550(KW)

式中Where n一減速器輸入軸轉速(r/min) n-input shaft rotating speed(r/min)

如果工作級别不是M5.可(kě)安式(2-1) 換算(suàn)至M 5工作級别的(de)功率Pm5.然後再根據Pm5

輸入轉速n和(hé)公稱傳動比i選擇減速器。

If the series is not M5,the series power Pmcan be calculated according to formula 2-1 ,and the decelerator can be selected on Pm,input rotating speed nand nominal transmission ration i.

選用(yòng)實例Selecting example:

1)一台起重量爲32t.跨度爲25.5m的(de)橋式起重機.其起升機構功率爲60Kw.轉速爲750r/

min.起升速度爲8m/min.機構的(de)工作級别爲M6.選擇減速器(減速器的(de)傳動比爲40,要求

第II種裝配型式,齒輪軸瑞)。

1)bridge cranc with weight of 32ton and span of 25.5m,the lifting structure power is 60Kw, the rotating speed is 750r/min,the lifting speed is 8m/min,the working series in M6.the related decelerator should be selected (transmission ratio is 40,the third installing form,gear shaft edge).

電機的(de)額定轉矩Rated torque: Mn=9550p/n=9550 x 60/750=764.8 N'm

根據《規範》附錄B,起升載荷分(fēn)配系數φ2=1+0.71v=1+0.71 x 8/60=1.1 According

to <stipulation>B,lift load factor φ2=1+0.71v=1+0.71 x 8/6=1.1

式中where

V-起升速度(m/s) V-liting speed (m/s)

動載系數: φ6=1/2(1+φ2)=(1+1.1)=1.05 loading factor φ6=1/2(1+φ2)=(1+1.1)=1.05

疲勞計算(suàn)基本載荷Mmax=φ6mn=1.05 x 764.8-803N.m

相對(duì)M6工作級别的(de)功率M6' spower

PMB=MMAX x n/9550=8038750/9550=63Kw

折算(suàn)成M5時(shí)的(de)功率related M5power

PM5-PM5 x 1.12(6-5)=63 x 1.12=70.65Kw

查表2-8,當n=710r/min,i=40時(shí),高(gāo)速軸許用(yòng)功率爲78Kw,相對(duì)的(de)減速器爲:

Check table 2-8,if n=7 10r/min,i=40 the allowed high-speed shaft power is 78Kw,the related decelerator is :

QJS200-40IIC或QJS-D500-40IIC型減速器。要求三支點用(yòng)前者,要求帶底座的(de)用(yòng)後者。

QJS500-40 IC or QTS-500-40 II C the former is for three-point sustaining and later is

for machine with stand.

2)一台雙梁門式起重機,其大(dà)車運行機構爲兩套,一套電動機的(de)額定爲7. 5Kw,轉速

n=1000r/min,工作級别爲M7 ,選擇起重機套裝式減速器,(傳 動比爲i=35.5,第II種裝配型式)。

2)a double-door crane,the operating structure is two sets,of which the motor power is 7.

5Kw,the rotating speed is n=1000r/min,working series is M7, to select a craning set decelera- tor (transmission ratio of 35.5 the second installing form)

電動機的(de)額定轉矩Motor rated torque

MN=9550p/n=9550 x 7.5/1000=71.7 N.m

疲勞計算(suàn)基本轉矩basic leale torque

MMAX=φ5φ8 x MN

取φ8=1.5,取φ8=1.4

Mmax=1.5 x 1.4 x 71.7=150.57

相對(duì)M7工作級别的(de)計算(suàn)功率calculated power for M7series

PM7=Mmax x n/9550=150.57 x 1000/9550=15.75Kw

折算(suàn)成M5時(shí)的(de)功率related power for M5

Pm5=Pm7 x 1.12(7-5)=15.75 x 1.122=19.75Kw

查表2-18,當n= 1000r/min,i=35.5時(shí),高(gāo)速軸的(de)許用(yòng)功率PM5=21Kw,相對(duì)應的(de)減速器爲QJG-T280-3551滿足要求.

Check table 2-1 8,when n=1000/r/min,i=35.5, the allowed power of high-speed shaft Pm5=21Kw,the related reducer QJG-T285-355 II can meets demands.