三、減速器的(de)承載能力及選用(yòng)方法

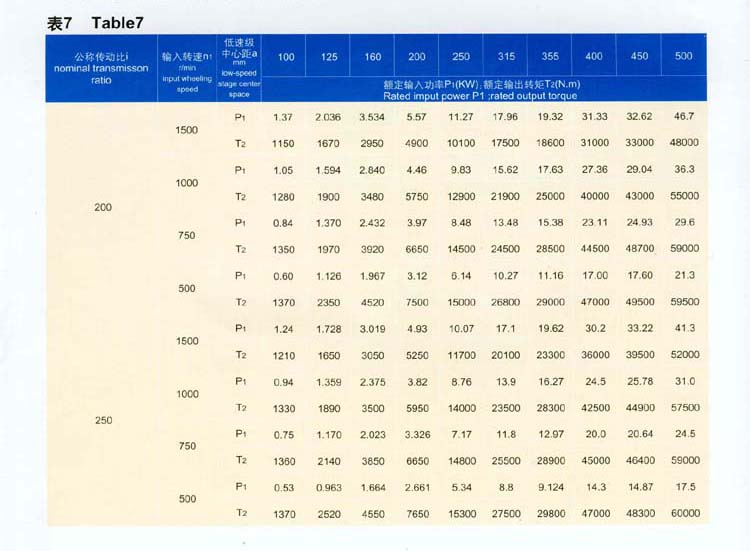

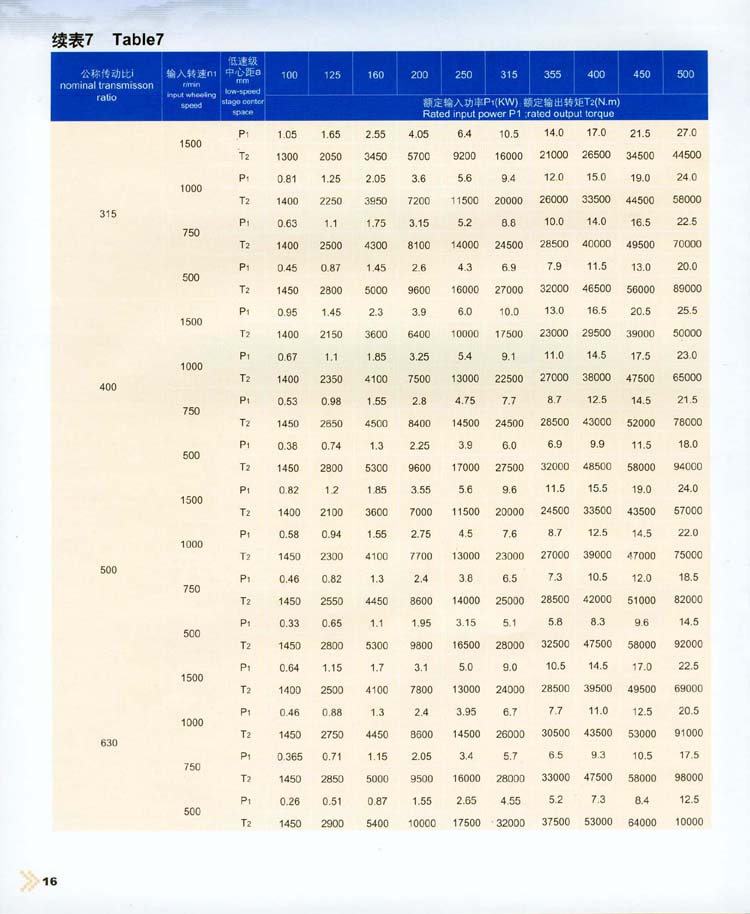

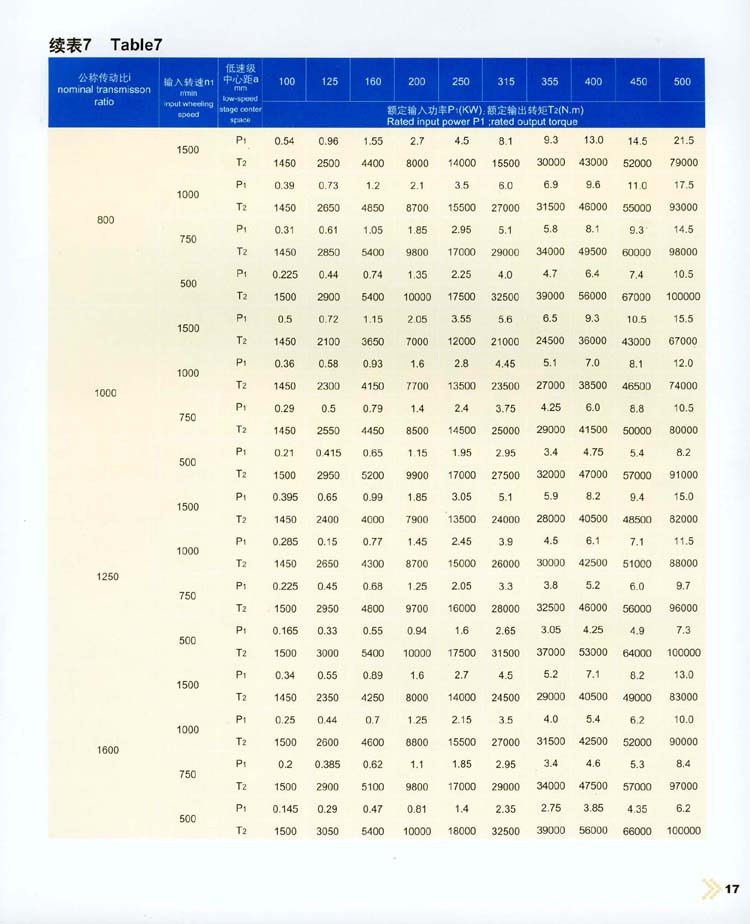

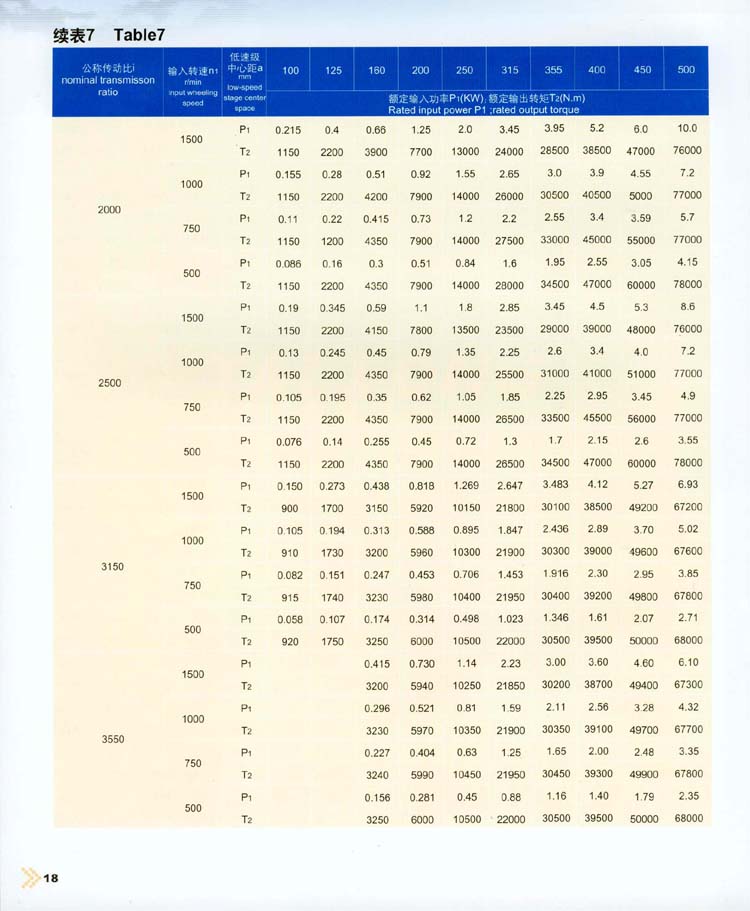

1. CCWU. CCWO及CCWS減速器的(de)額定輸入功率P1及輸出轉短T2應符合表7的(de)規定。

Rated imput power P1 and output torque T2 of CCWU,CCWO,and CCWs reducers Confor to stipulation of table 7

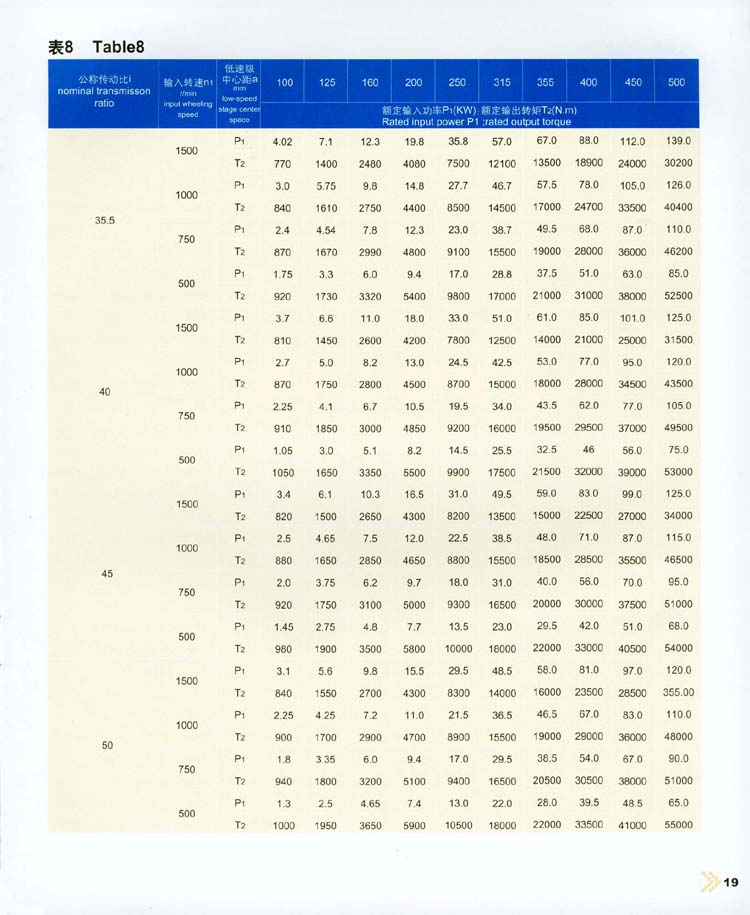

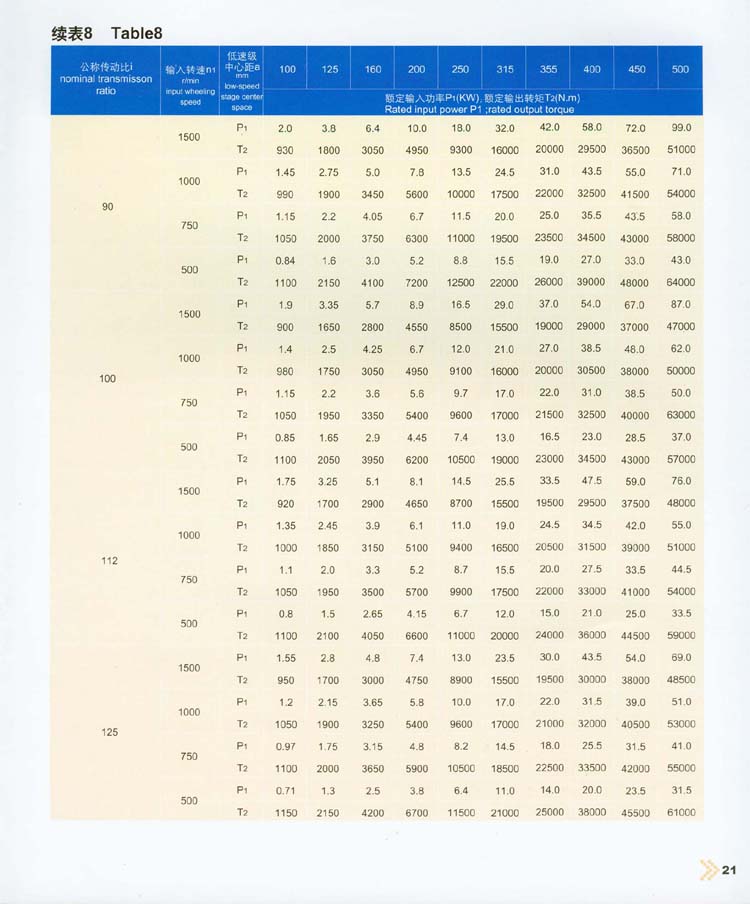

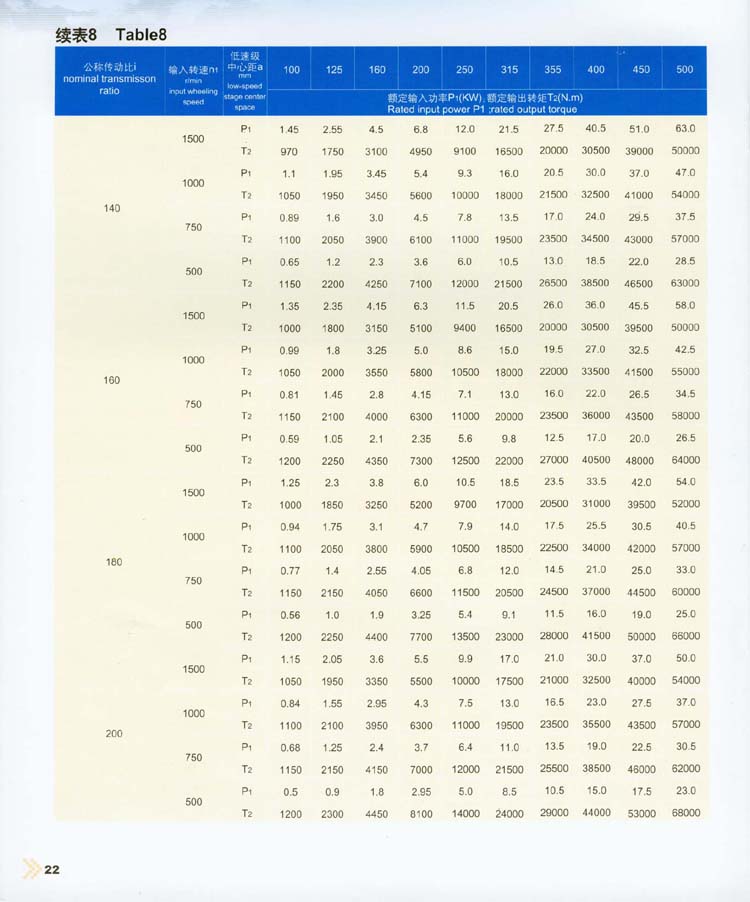

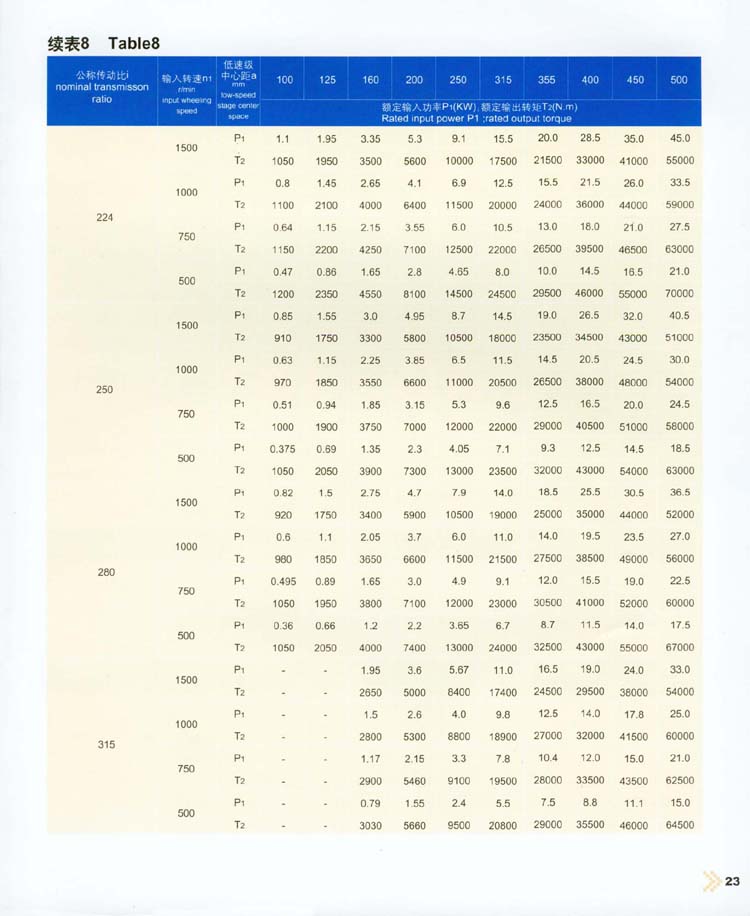

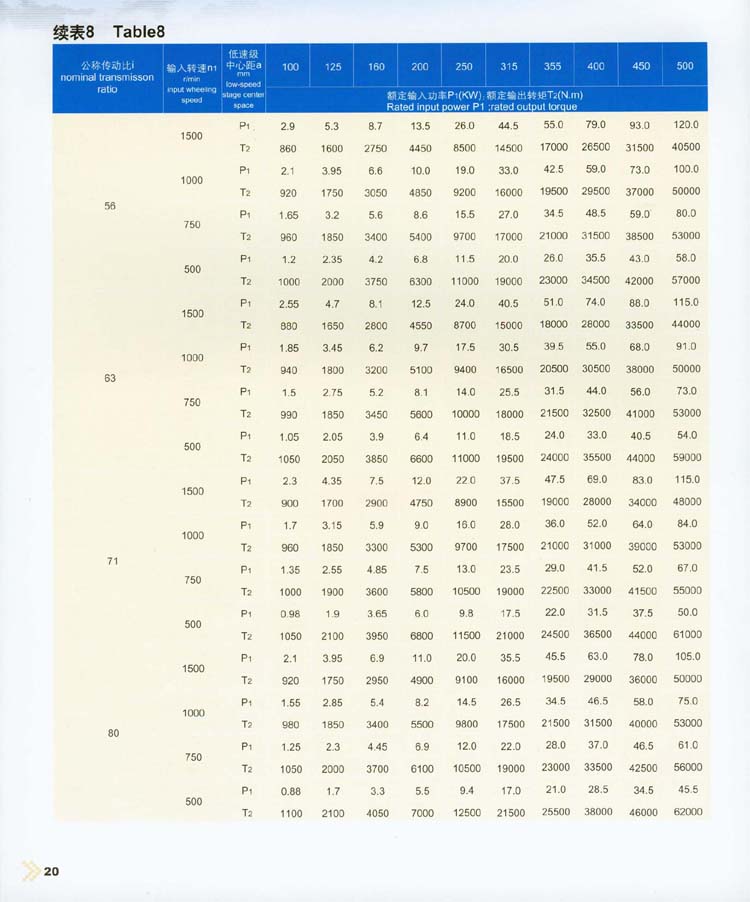

2. GCWU. GCWO及GCWS減速器的(de)額定輸入功率P1及輸出轉短T2應符合表8的(de)規定。

Rated imput power P1 and output torque T2 of GCWU,GCWO,and GCWS reducers Conform to stipulation of table 8

3.減速器輸出軸軸端的(de)許用(yòng)負荷及确定方法應符合GB9147-88附錄C中C4的(de)規定。

Allowed load of output shaft conforms to stipulation of GB9147-88 appedixC-C4

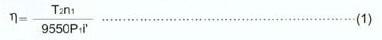

4.減速器的(de)效率應分(fēn)别依據表7.8中的(de)P1及T2由下(xià)式計算(suàn)。Eficiency is calculated by the formula below according to P1.T2 in table7.8

式中爲減速器的(de)實際速比。of which P-atual speed rate.

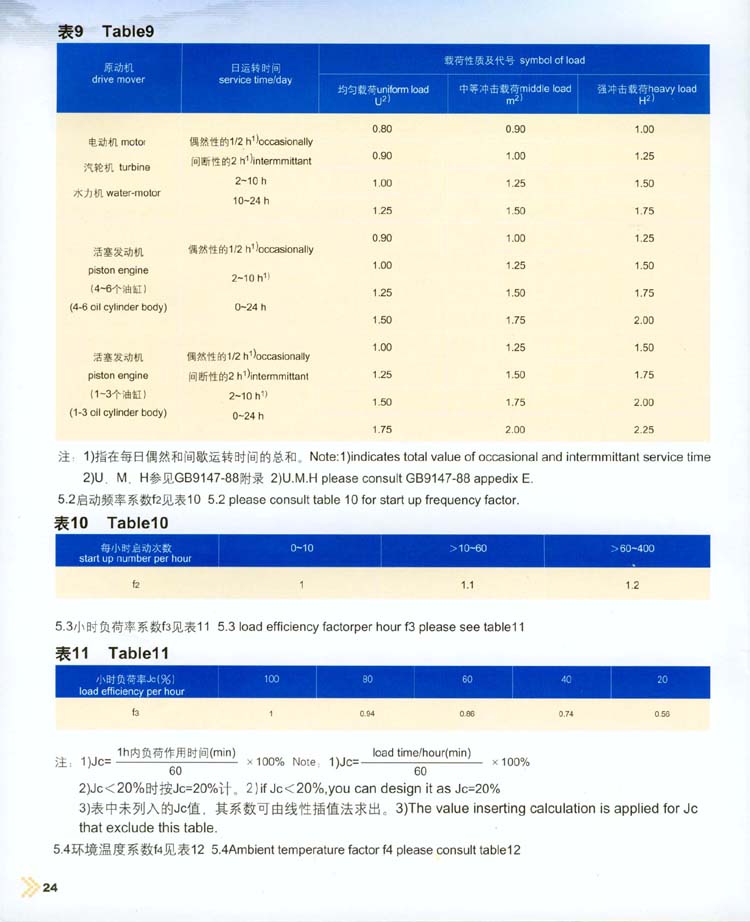

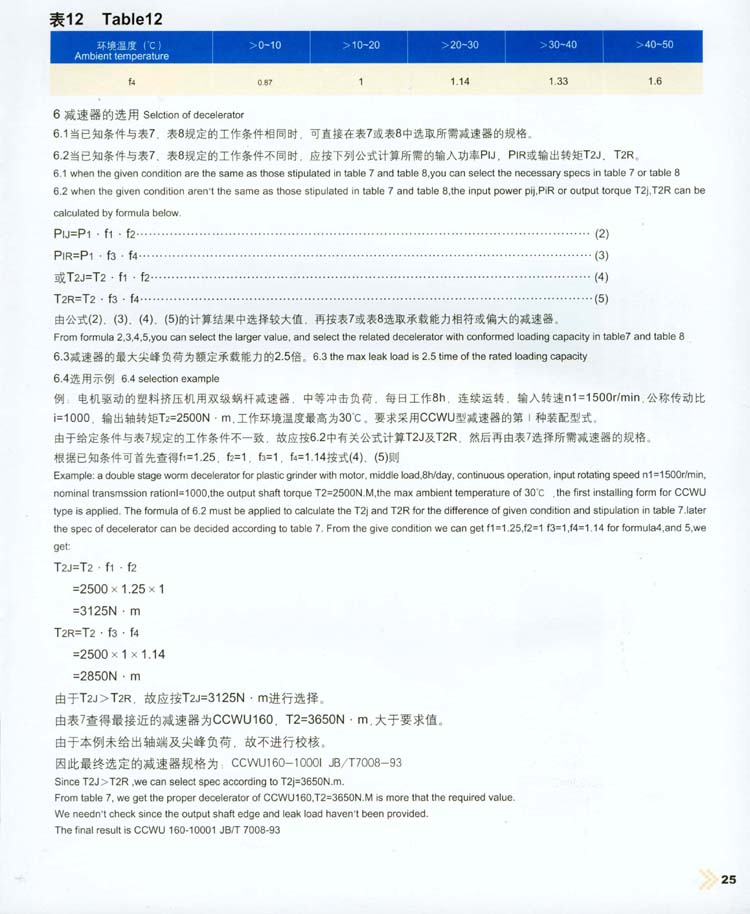

5.表7.表8中的(de)額定輸入功率P1及額定輸出轉矩T2适用(yòng)于如下(xià)工作條件:減速器工作負荷平穩無沖擊.每日工作8小時(shí),每小時(shí)啓動10次,小時(shí)負荷率Jc= ****,環境溫度20C.極限油溫100'C。 當上述條件不滿足時(shí),應依據表9-表12進行修正。

5.The working situation is as fllows, stable working load,8 hours/day, starup 10 times/hour, load eficieney JC= **** per hour,ambient temperature 20'C ,max oil temperature 100'C

5.1載荷系數f1見表9。5.1load factor f1 is show in table 9