硬齒面圓柱齒輪減速器

Series of Carbide-Faced Cylindrical Gear Decelerators

一、概述Brief

硬齒面減速器主要包括平行軸系列和(hé)垂直軸系列,平行軸減速器是按******标準(GB19004-88))生産,産品經優化(huà)設計,具有國際八十年代先進水(shuǐ)平,它主要包括ZDY (單級)、ZLY (兩級). ZSY (三級)和(hé)ZFY (四級)四大(dà)系列,垂直軸減速器是按******标準(JB/T9002-1999)生産.用(yòng)于輸入軸與輸出軸呈垂直方向布置的(de)傳動裝置,它主要包括DBY. DCY和(hé)DFY三大(dà)系列。

Decelerator with hard tooth surface includes parallel shaft and vertical shaft. Parallel shaft decelerator is manufactured according to national standard (GB19004-88) .The products are optimized to advanced standard in 1980s. It includes 4 series of ZDY (single stage), ZLY (2-stage),ZSY (3-stage) and ZFY (4-stage). Vertical shaft decelerator is manufactured according to national standard (JB/T9002-1999) and used as driving device that has vertical arrange-ment of input or output shaft, and it includes 3 series of DBY。DCY and DFY.

1、性能特點Properties

(1)中心距,公稱傳動比等主要參數均經優化(huà)設計,主要零,部件互換性好。

(2)齒輪均采用(yòng)優質合金鋼經滲碳、淬火、而成,齒面硬度達HRC54-62.

(3)體積小、重量輕、精度高(gāo)、承載能力大(dà)、效率高(gāo)、壽命長(cháng)、可(kě)靠性高(gāo)、傳動平穩、噪音(yīn)低.

(4)一般采用(yòng)油池潤,自然冷(lěng)卻,當熱(rè)功率不能滿足時(shí),可(kě)采用(yòng)循環油潤滑或風扇,冷(lěng)卻盤管冷(lěng)卻。

(1) Preferential design is applied such as main parameter center distance and nominaldrive ration, which guarantee good interconnection between key parts and components.

(2) All gear wheels are made of quality alloy steel and treated with carburetion andquenching,with tooth surface hardness up to HRC 54-62.

(3) Small size, light weight, high precision, large carrying capacity, high efficiency, longservice life, high reliability, stable driving, and low noise.

(4) Normally oil sump lubrication is used, with cooling naturally. If thermal power can notbe achieved, circular oil lubrication or fan may be used, and cooled with cooling coil pipe.

2、應用(yòng)範圍Application

(1)輸入轉速一般n,≤1500r/min.

(2)齒輪傳動圓周速度不大(dà)于20米/秒。

(3)工作環境-4050'C.如果低于0"C.啓動前潤滑油應預熱(rè)至0C以上,本減速器可(kě)用(yòng)

于正反兩個(gè)方向運轉。

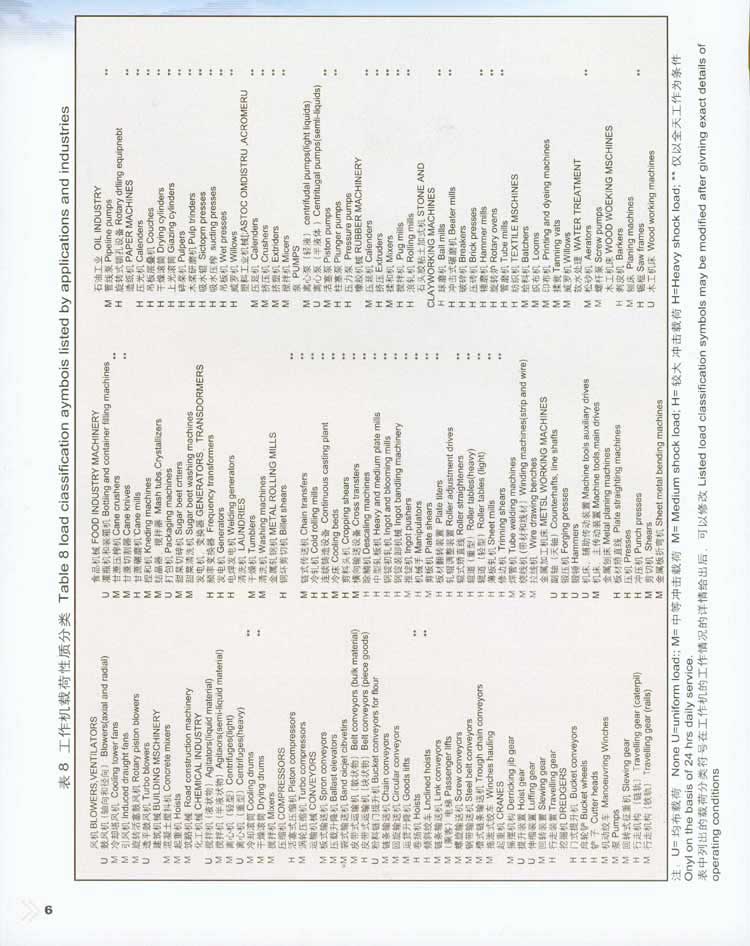

(4)可(kě)廣泛用(yòng)于冶金、礦山、化(huà)工、建材、起重,運輸.紡織、造紙、儀器、塑料、橡膠,工程機械、能源等工業部門。

(1) Input rotate speedn, is≤1500r/min.

(2) Gear wheel driving peripheral speed is < 20m/sec.

(3) Ambient temperature is -40 50C. Ifitis < 0'C, Lubricant should be preheated to> 0'C before startup. Running both forward and backward are available for this decelerator.

(4) Applicable for the industries such as metallurgy, mine, chemical industry, construction materials,hoisting, transportation,textile, paper making, paper making, food, plastic, rubber, engi-neering machinery and energy industry.

說明(míng),用(yòng)戶帶逆止器時(shí),若需長(cháng)軸系列,請在訂貨時(shí)注明(míng),訂貨來(lái)注明(míng)者視爲按标準(樣本)制造。

Note: The products would be manufactured according to standard(or sample) unless specifical condition is

listed in the related order when a holdback is needed to be connected to shaft series.

二、選用(yòng)方法Selection procedure

1、已知參數和(hé)條件Given following information

原動機名稱,功率P,= kW轉速n,= r/min

工作機名稱功率P2= KW轉速n2= r/min

要求的(de)傳動比i=n,/n2

每天工作小時(shí)數h, 每小時(shí)啓動次數次, 每小時(shí)運轉周期%.

負荷特點(平穩、沖擊、嚴重沖擊),可(kě)靠度要求(一般、較高(gāo)、高(gāo))

環境溫度C,現場(chǎng)散熱(rè)條件,冷(lěng)卻水(shuǐ)溫度C

聯軸器型式,齒輪軸軸伸上是否還(hái)要承受其他(tā)附加力

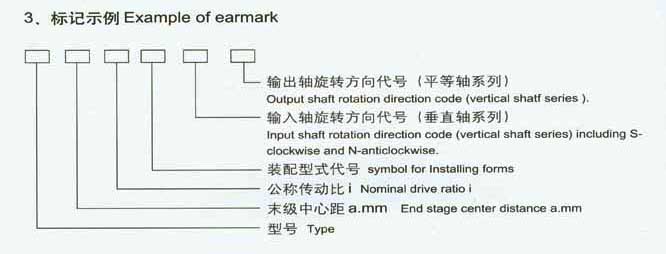

裝配方式型,輸出軸旋向(雙向旋轉時(shí)請說明(míng)主旋向)

有無其他(tā)特殊要求

Type of prime mover, power P, in kW, speed n, in r/min

Type of driven machine, power P2 in kW, speed n2 in r/min

Required total transmission Tatio i=n/n2

Average daily operating time in hours, starts per hour, operating cycle per hour ,operating cycle per hour in%

Loading nature (uniform, moderate shock, heavy shock).required relibility (normal,high, higher).

Ambient temperature in ,elimination of heat in work spot, cooling water temperature in C.

Type of coupling.

Any additional force acting on shaft extension.

Assemble style, direction fo rotation of output shaft (of both directions, please show the main direction).

Any other special requirements.

2.按額定功率選擇規格型号Selecting the size according to nom

平等軸系列齒輪箱的(de)公稱輸入功率P.(表9-20)按載荷平穩,每天工作時(shí)間小于或等于10h.每小時(shí)啓動不超過5次,允許啓動轉矩爲工作轉矩的(de)2倍,單向運轉,單對(duì)齒輪的(de)接觸強度安全系數約爲1.失效率概率小于或等于1%等條件計算(suàn)确定的(de)。齒輪箱雙向運轉時(shí),需視情況将P,乘上0.8-1.0的(de)系數,當反向載荷大(dà),換向頻(pín)繁,選用(yòng)的(de)可(kě)靠度系數Ka較低時(shí),系數取較小值,反之取較大(dà)值。

The nom.power ratings P, of parallel gear units (table 9 to 20) are valid for shock-free operation of no more than 10hrs/day and up to 5 starts per hour, permitting a starting torque of two times to the running tourque, unidirectional rotation, the safe factor of contact strenth of single of gears is about 1,and failure probability≤1%. For both directional rotation,P、 shoud be multiplied by a factor of 0.8 to 1.0, in accordance with the actual conditions. A lower factor is selected if the reverse load is selected. While the reverse load is high, the change of direction is requent and a low reliability factor Kp taken; otherwise a higher value should be selected.

所選齒輪箱的(de)額定功率必須滿足,PC=P2KAKSKR≤PA

The nom. power of gear must meet:

式中:

PC-計算(suàn)功率Calculated power

P2-工作機功率Driven machine power

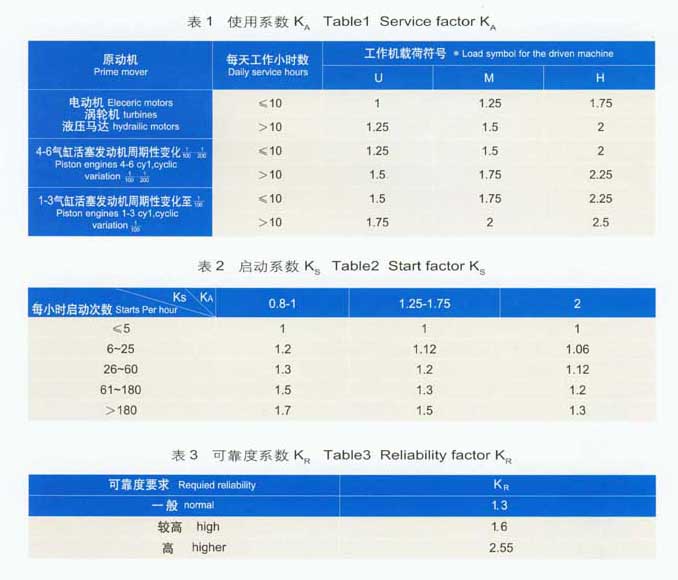

KA-使用(yòng)系數,見表1 Service factor, see table 1

KS-啓動系數,見表2 Start factor, see table 2

KR-可(kě)靠度系數,見表3 Reliability factor, see table 3

3、按許用(yòng)熱(rè)功率校核Check on thermal power rating

平等軸系列齒輪箱的(de)許用(yòng)熱(rè)功率P,适用(yòng)于環境溫度20'C.每小時(shí)****連續運轉和(hé)功率利用(yòng)率(P2/P1,****)爲****的(de)情況,條件不同進,須進行修正。

The themal capacities Pt of vertical series gear units is valid for an ambient tempera-ture of 20'C, an operating cycle of **** per hour and a gear tilization of ****(P2/P1 ****=utilization in %)

所選齒輪箱應滿足: Pct=P2KTKWKP≤ PT

Otherwise they must be corrected for the selected gear unit, the following formula

shoule be neet:

式中

PCT-計算(suàn)熱(rè)功率Calculated power

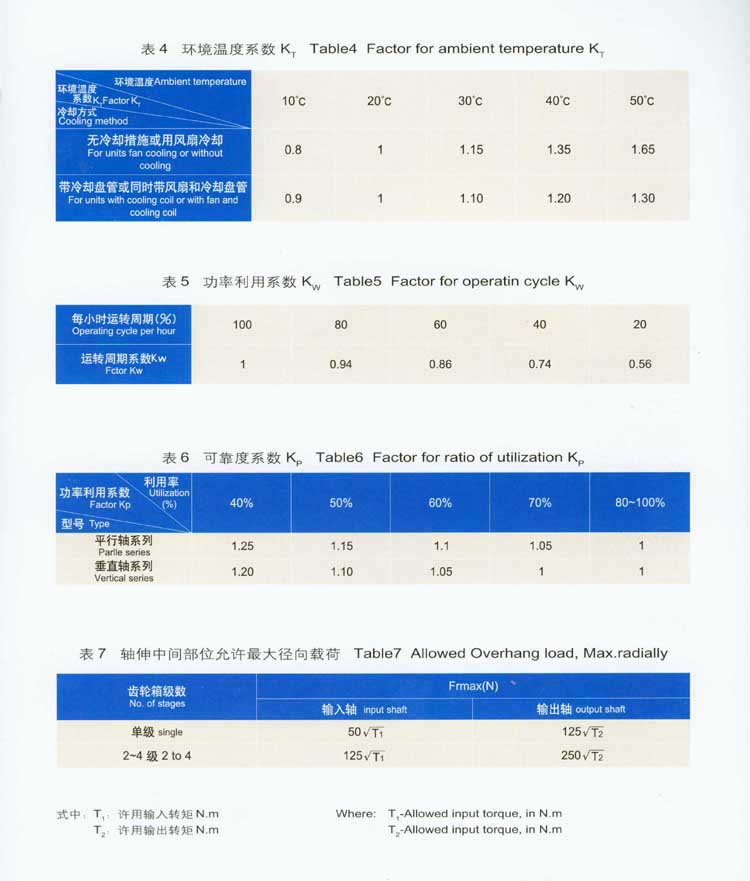

KT--環境溫度系數,見表4 Factor for ambient temperature, see table 4

KW運轉周期系數,見表5 Factor for operating cycle, see table 5

KP-功率利用(yòng)系數,見表6 Factor for utilization, see table 6

4、校核、軸伸部位承受的(de)徑向載荷Check radial load on shaft extension

齒輪箱的(de)輸入軸和(hé)輸出軸中間部位承受的(de)徑向載荷Fr應低于表7的(de)數值

The overhang radial force Fr on input shaft or output shaft should not exceeded the values listed in table 7